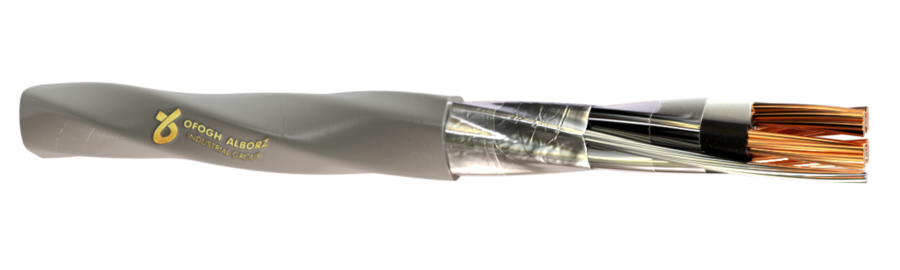

Instrumentation Cables

Instrument cables are cables that are responsible for transmitting signals and data. These cables are designed to be resistant to electromagnetic interference and noise.

The latest standard used to manufacture and test instrument cables as well as control cables is BS EN 50288-7, but a wide range of applicants still use older standards such as BS 5308.

The type of wire placement in Instrument cables is multi-core, pair, triple and quad. Each of the handles may be placed inside a sheath (Individual Screen) and then twisted together, and the overall set of twisted strands is placed inside the final shield (overall screen).

In the structure of instrument cables, the conductor type is generally type 2 or flexible, but according to customers' requests, it is possible to produce with other classes such as core (class 1) or flexible (class 5). Copper conductor material can also be used as plain copper or tin-coated.

Also in the extrusion stages (such as insulation, inner cover, final sheath) according to the conditions of the places used, it is possible to produce with polymers of polyethylene (crosslinked or plain), PVC, halogen free.

There are three ways to shield or screen cables. The most common method is to use aluminum foil tape with a 0.5 flexible tin-coated wire. The second method is to shield the cable using a plain or coated metal braid with a minimum coverage of 85%. There is another method that combines the above two methods using aluminum foil and braid shield with a minimum coverage of 43%.

At the customer's request, it is possible to amoured the instrument cables in two forms: wire (common) and galvanized wire, which is placed on the inner cover of the cable. The output voltage range of Instrument cables is 500 volts, although it is possible to produce with voltages of 90 and 300 volts.

Abbreviations Symbol for instrument cables

|

Outdoor cable |

A |

Identifications of designation |

|

Installation Cable |

J |

|

|

Installation cable for Industrial electronic |

RE |

|

|

(PVC) Poly vinyl chloride |

Y |

Insulation materials |

|

(XLPE) Cross Linked Polyethylene |

2X |

|

|

(PE) Poly ethylene |

2Y |

|

|

Screen of braided copper wire |

C |

Screening |

|

Screen of plastic-coated metallic foil+ Drain wire +polyester tape |

(st) |

|

|

PVC |

Y |

Sheath material |

|

(PE) Poly ethylene |

2Y |

|

|

Halogen free |

HX |

|

|

(PVC) Poly vinyl chloride heat resistant |

Yw |

|

|

Steel wire braid |

(z) |

Type of armour |

|

Steel tape armour |

B |

|

|

Pair in metal foil |

Pimf |

Type of stranding elements |

|

Triple in metal foil |

Timf |

|

|

Quad in metal foil |

Vimf |

Abbreviations Letter for instrument cables

|

Copper conductor |

CU |

|

Tinned copper conductor |

TCU |

|

Individual screen |

ISCR |

|

Overall screen |

OCSR |

|

Mica glass tape |

MGT |

|

Aluminum foil |

AL Foil |

|

Stranded tinned copper |

Drain Wire |

|

Polyester Tape |

Pet |

|

Crosslink Polyethylene |

XLPE |

|

Steel tape armour |

STA |

|

Steel wire armour |

SWA |

|

|

SWB |

|

Aluminum tape armour |

ATA |

|

Aluminum wire armour |

AWA |

|

Halogen free granule |

LSFOH |

|

Polyvinyl chloride |

PVC |

The technical specifications of instrument cables are as follows: